Leverage and Linkages

Once upon a time in the distant past (about 1973), motorcycle rear suspensions were quite similar to the front: there was a pair of shocks,

each with a spring not so different to a fork spring. The shocks themselves were relatively skinny things and they were bolted at the very

back of the bike, nearly directly above the axle. It was pretty obvious that the shock moved almost one to one with the wheel. Figure 1a In fact, which system doesn't really matter. Either allows a clever engineer a wide choice of leverage curves by changing

the lengths and proportions of the various components.

Leverage and Linkages

Leverage and Linkages

That all changed when the motocross world realised that having some extra travel at the back was a major competitive advantage, but there

was simply no room for shocks that had 150mm of travel, let alone the 300+ that is common now. So they started using leverage; by moving

the shocks forward on the swingarm, they could get more travel from the same shocks.

They also got shocks that faded rapidly and occasionally exploded (the first ones weren't pressurised, so the oil turned to foam and got

very hot, plus the seals weren't designed for the higher pressure). Technology took a while to catch up.

Also in the seventies, Yamaha hit on the idea of using a single, long shock absorber mounted under the seat and tank. This had a couple

of advantages: it coupled the rear suspension forces directly to the steering head, allowing the rear subframe to be made much lighter;

the triangulation of the swingarm required to mount the shock also made it (the swingarm) less susceptible to twisting; the shock forces

didn’t make the rider's seat move about and make him think he was about to crash. At the same time they bought the rights to use the de

Carbon shock design, which separated the oil from pressurized nitrogen gas. That's the system that is still in use by every modern

high-performance motorcycle shock.

It turned out that the single shock system was also a boon in road racing, probably because of the reduced flex. Suzuki and Kawasaki,

then Honda, released competing systems and the canonical motorcycle came to have only one rear shock absorber, connected by some sort

of linkage system. Aside from being an excuse for the marketing department to come up with cool names like "Monocross", "Full-floater"

and "Uni-Trak", these linkages gave the opportunities for engineers to experiment with variable rate linkage systems.

What’s a variable rate linkage system, then?

I think the idea of leverage is pretty obvious to anyone who has used a nut-cracker, a bottle-opener or a tyre lever. A small amount of

force moves one end of a lever a longish distance, while the other end applies a lot of force but only moves a small distance. Attach

the wheel at the long distance, easy end and the shock at the short, hard end and you've got most of it. The tricky bit is to arrange

it so the ratio between the forces changes as the whole thing moves. Again this was great for the MX guys: they could set their bikes

soft enough to absorb the smaller bumps without losing traction, but when landing from jumps the rear suspension moved into the stiffer

part of its travel to avoid bottoming.

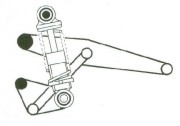

One simple example of how to do this comes from the old twin-shock design. If you can remember what one looks like (helped by the

occasional marketing of nostalgic replicas), the shocks were usually tilted forward a bit from the vertical. Now in fact this is another

way of changing the leverage: what counts is the perpendicular distance from the shock to the swingarm pivot. Another way of putting it

is the shortest possible distance from the swingarm pivot to the centre-line of the shock. So as the shock leans forward, it gets closer

to the pivot and so the leverage changes. You'll be familiar with this effect if you’ve ever used a spanner: pulling at anything other

than at right angles to the spanner applies less torque to the bolt.

Some manufacturers (Montesa, for example) saw this as a cheap way to build "long travel suspension", since they could leave their swingarm

unmodified. It turns out this didn't work too well for two reasons. One was that they missed out on the accidental benefit to torsional

stiffness from strengthening their swingarms. The other was that the arrangement caused the shock-to-swingarm angle to close up as the

suspension compressed (see the first pair of diagrams). This is inevitable if the top shock mount is closer to the pivot than the one on

the arm. That meant the rear axle had progressively more leverage over the shocks, so the rear suspension became softer as it compressed…

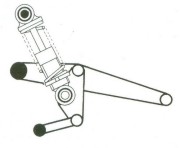

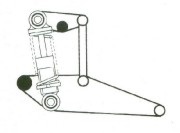

soft on big bumps, hard on small ones. Today, we'd call this "digressive". Compare that to the second pair of diagrams, where the shock

is more upright: as the suspension compresses, the angle between swingarm and shock increases, so the suspension is rising rate.

With single shock systems there are essentially two distinct linkage systems (plus the option of just bolting the shock directly onto the

swingarm, as with KTM and various low budget bikes like the VTR250). Both have a 3-pivot linkage (rocker arm, bell-crank), with one of

its pivots bolted to one end of the shock (usually the bottom, but the top for the Ducati system which is the old Kawasaki Uni-Trak and

Suzuki Full-Floater, as well as some of the exotic variants of the Honda Pro-link seen on works road racers). Another one of the pivots

attaches to a straight connecting rod (or pair of them), often called a dogbone because of the way it is enlarged at each end where it

is attached. The third pivot attaches to either the frame (Suzuki GSXR’s, Kawasaki ZXR, Yamaha GP bikes, Ducati) or the swingarm (Honda

Pro-link, Yamaha R1 and R6). The far end of the dog bone connects to the swingarm if the linkage connects to the frame, or vice-versa.

So what are the two systems?

The other end of the shock can either connect to the same thing as the dogbone, (Honda non-unit prolink, Yamaha R1 & R6: fig 2a; Ducati,

fig 2b) or the same thing as the linkage (the rest). By the way, despite all the mystical marketing clap-trap, the Honda Unit Pro-link

(fig 1b) works exactly the same way as the Suzuki (fig 1a), except that the role of swingarm and frame are reversed. Since only the relative

angle between them matters, this makes it the same thing.

In the same way, the Ducati system is a back-to-front version of that on the R1.

figure

2a

figure

2b

So what does the leverage do exactly?

Imagine for a moment a nice simple twin shock system where the shocks are bolted on halfway along the swingarm. If I apply some

upward force F to the rear axle (by sitting on the bike, for example), then basic principles of leverage mean twice that amount of

force, 2F, is being applied to the shocks.

You might think then that the springs would need to be twice as stiff. You'd be wrong. Applying twice the force to a given spring makes it

move twice as far (2F/k), but the distance moved by the shock gets multiplied by the leverage ratio on the way back to the rear axle. So

the axle moves twice as much as the shock, or 2 x 2F/k = 4F/k. That's FOUR times as much as if the shocks were bolted on right at the axle.

In general, if the leverage ratio between the axle and shock is r, then the spring needs to be r x r = r2 as stiff. As a sanity check,

think about a bike like a 2004 R1 that has almost exactly a 2:1 leverage ratio. It has a pair of 9N/mm forks springs, so to get the

same spring rate at the rear axle as the front, the shock spring needs to be twice as stiff because there is only one shock but two

fork springs. Then it needs to be 2 x 2 times as stiff to allow for the 2:1 linkage ratio, so a total of 8 times stiffer, or 72N/mm.

In fact the stock spring is about 90N/mm, because with a rider on board there is more weight at the back than the front, and because

of the front leverage ratio.

What?

Yes, the front leverage ratio. The forks are not vertical, so the fork springs have to compress about 1.1mm for every 1mm of vertical

axle movement. That means the effective spring-rate at the front axle is about 20% greater than the sum of the fork spring rates. On

the other hand, the rake of the forks also means they have to hold back the bike under braking, and provide a greater component of the

turning force during cornering. That would get us into the theory of pro-dive and anti-dive, or the same thing for the rear, called squat.

That's a story for another time.

What are typical ratios?

Plotted below are comparative graphs of the leverage ratios of three bikes: a 2003 SV650 (a sporty commuter); a 2005 GSXR1000

(ridiculously powerful, raceable street bike); and a 2003 TZ250 (2-stroke 250 GP bike). Notice that SV curve is quite different to

the other two, in that it's a lot more progressive. This is what most street bikes used to look like, or they were even more progressive.

The current GSXR1000 is almost the same shape as the TZ250, which is a no-compromise race bike, whereas earlier GSXR’s were more progressive.

It's a similar story with other brands: the Yamaha R1 became much less progressive than the earlier models. Kawasaki went to the extreme:

the curve for the 2004 ZX10R actually slopes ever so slightly up, rather than down. That means the suspension become slightly softer as it

compresses, as discussed above.

The second plot gives the effective spring rate at the rear axle for each of the same three bikes. Note that the downward slope of the

leverage ratio has become a (steeper) upward slope: the axle spring rate is the reciprocal of the square of the leverage, multiplied by

the rate of the actual spring.

© Graham Byrnes

Leverage and Linkages - Q & A

Does a different leverage need a different shock?

A different overall ratio, definitely. Most road bikes have about 130mm rear wheel travel, so to get that with different average

ratios you need shocks with different amount of shaft travel. A 2002 GSXR shock will have about 74mm shaft travel, while a Fireblade

from the same year has 20mm less... but both have about the same wheel travel. As a result, the Fireblade will need a spring about

twice as stiff, with corresponding stiffer damping.

But what about the progression?

You need to keep it in mind when you look for a set-up. A less progressive linkage will be stiffer initially… so if you try to make it

feel the same as a more progressive one while bouncing up and down in the garage, it will be too soft on the track or road. If you are

making valving changes, this needs to be considered as well.

You should also be aware if your shock has a top-out spring or not (late model Ohlins and WP shocks do, for example). As discussed

in an earlier article, this can make the first part of the travel feel much stiffer.

So what works best?

It depends what you want it to do, of course. At WSB or GP level, teams carry a collection of different linkages to use for different

track conditions. A bumpy track will need something different to a smooth one… and it will depend where the bumps are: going into

corners (want it soft initially), mid-corner (not too stiff mid-travel) or coming out (whatever works!) and what sort of corners

(long fast corners, or short corners with hard acceleration). In general race linkages tend to be less progressive than road bikes

(see the graphs), since that works better mid-corner and resists squat better on the exit. There was a "race kit" linkage sold by

HRC for the 2004 CBR1000RR which made the leverage ratio less progressive (more like an R1). On the other hand, Graves Performance

in the US sold a linkage for the 2002 R1 that was more progressive for use on bumpy tracks (it was still less progressive than the

2001 model stock linkage).

Can I change my bike’s leverage curve?

Some people change the dogbone lengths. This usually has a fairly small effect on the leverage ratio and a big effect on the ride height.

It can give some improvement if it’s possible to change the shock length to keep the ride-height reasonable. It is reasonably easy to make

new dogbones for most bikes, plus this is legal for e.g. Australian Production Superbike.

If you want to make significant changes, you'll need to change the linkage. On an R1 or R6 that’s relatively easy, since the linkage is made

out of two flat plates. On other bikes it means machining a new piece from billet (or buying one from HRC or Yoshimura etc etc). It's

tempting to try swapping linkages from other bikes: putting a linkage from a 2005 GSXR1000 into a 2003 SV650 would work beautifully…

if the shock would still fit through the swingarm!

What if the linkage wears?

This will cause small changes to the leverage ratio, and big problems elsewhere: free-play means the rear-wheel has some undamped movement,

which can cause it to go into oscillation. Yamaha street bikes are infamous for having a lot of play in the suspension, even brand-new.

What if I change gearing?

This can actually have a big effect. Every change of total sprocket teeth by 1 will require moving the axle back or forward by 4mm.

So if you put a 3 tooth larger rear sprocket on, you’ve just shortened the swingarm by 12mm. Now on a bike with a relatively short swingarm

(GSXR, or especially a Ducati) that will be about 2.3%. However, remember that the spring rate changes as the square of the leverage, so you

will have changed the spring rate at the rear wheel by almost 5%. That's about one step in common spring rates: similar to swapping a 95N/mm

spring for a 100N/mm.

Does it affect preload?

Yes, systems with bigger overall ratios, need less preload (if measured in length). If you imagined that your shock was allowed to

extend until there was no preload on the spring, that would move the axle down by different amounts depending on the (initial) leverage

ratio. Think of that as "axle-equivalent preload". Now if the bike weight and the effective spring rate at the rear axle are the same,

getting the same ride height will require the axle-equivalent preload to be about the same. However if the leverage is greater, this

will mean less movement at the shock, hence less preload (and usually, a stiffer spring).

© Graham Byrnes